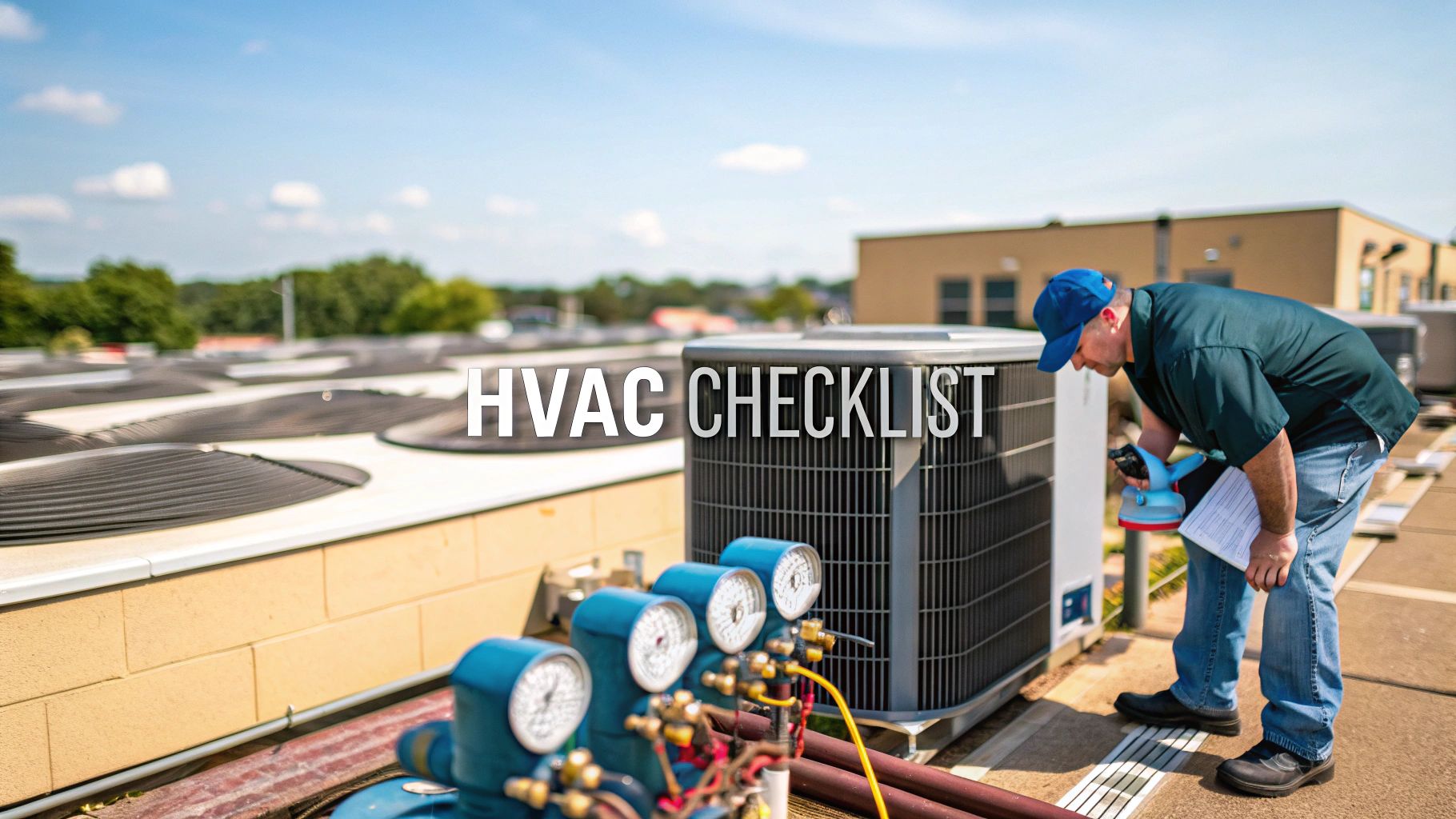

A commercial HVAC system is the heart of any business, regulating temperature, ensuring air quality, and protecting valuable equipment. However, without a structured approach to upkeep, this critical asset can become a major liability, leading to soaring energy bills, unexpected downtime, and costly emergency repairs. A proactive maintenance strategy is not just about preventing failures; it's about optimizing performance and extending the lifespan of your equipment. For any business owner or property manager, especially in climates like Palm Beach County, neglecting this system is a direct threat to operational stability and profitability.

This comprehensive commercial hvac maintenance checklist breaks down the eight most critical areas of focus, providing actionable steps and expert insights to keep your system in peak condition. Following this guide will help facility managers, business owners, and maintenance teams ensure their systems run efficiently and reliably year-round. It transforms maintenance from a reactive chore into a strategic advantage, safeguarding comfort and your bottom line.

Think of this checklist as a foundational component of your overall facility management plan. To ensure comprehensive safety beyond just HVAC, consider implementing a broader workplace inspections checklist that covers all critical areas of your facility. By integrating specialized checklists like this one into a larger safety framework, you create a robust system that protects your people, property, and profits. Let’s dive into the essential tasks that will keep your commercial HVAC system running smoothly.

1. Air Filter Inspection and Replacement

The single most impactful task on any commercial HVAC maintenance checklist is inspecting and replacing air filters. Think of filters as the lungs of your HVAC system. They trap dust, pollen, debris, and other airborne contaminants, preventing them from circulating throughout your building and clogging sensitive system components.

When filters become dirty, they force the system's fan motor to work harder to pull air through, leading to increased energy consumption and premature wear and tear. This simple, routine task is your first line of defense against poor indoor air quality, reduced system efficiency, and costly, avoidable repairs.

Why It's a Critical First Step

Ignoring filters is like trying to breathe through a clogged straw. The entire system strains, efficiency plummets, and the air you breathe suffers. Regular replacement ensures optimal airflow, protects expensive internal components like evaporator coils from accumulating dirt, and maintains a healthier environment for employees and customers.

- Office Buildings: A quarterly filter replacement schedule can significantly improve air quality and has been shown to result in energy savings of up to 12% by reducing the strain on air handlers.

- Hospitals: Healthcare facilities often use high-efficiency HEPA filters and require monthly inspections to maintain sterile conditions and protect vulnerable patients.

- Manufacturing Plants: Environments with heavy dust or particulates may need weekly filter checks to prevent system failure and maintain air quality standards.

Actionable Tips for Implementation

To make filter maintenance a seamless part of your operations, integrate these best practices:

- Create a Detailed Log: Maintain a logbook or digital record near each air handler. Note the date of change, the type of filter used (including its MERV rating), and the technician's initials. This history is invaluable for troubleshooting and planning.

- Stock Essential Filters: Keep a supply of common filter sizes on-site. This simple step prevents downtime and ensures replacements happen on schedule, rather than waiting for an order to arrive.

- Install Pressure Gauges: A differential pressure gauge measures the pressure difference before and after the filter. It provides a clear, data-driven indicator of when a filter is clogged and needs replacement, removing guesswork.

This quick reference summarizes the core principles of effective air filter management.

These key takeaways highlight how consistent, proactive filter care directly translates into measurable energy savings and optimal system performance.

2. Refrigerant Level Check and Leak Detection

Proper refrigerant levels are the lifeblood of your commercial HVAC system's cooling capabilities. This critical task involves verifying the system has the correct amount, or "charge," of refrigerant and proactively searching for leaks. Refrigerant absorbs heat from your indoor air and releases it outside, but if the levels are too low, the system cannot cool effectively.

A system with low refrigerant is forced to run longer and harder to achieve the desired temperature, driving up energy bills and putting immense strain on the compressor, one of the most expensive components to replace. This step in the commercial HVAC maintenance checklist is not just about performance; it's about protecting your investment and ensuring environmental compliance.

Why It's a Critical Second Step

An incorrect refrigerant charge can cripple system efficiency and lead to catastrophic equipment failure. Even a minor leak can result in a significant loss of cooling power and release harmful greenhouse gases into the atmosphere. Regular checks ensure your system operates at peak capacity, avoids costly compressor damage, and adheres to EPA regulations.

- Large Retail Chains: Implementing quarterly refrigerant audits across all locations can reduce leak-related cooling failures and has been shown to lower associated repair costs by up to 30%.

- Data Centers: These critical facilities often use continuous refrigerant monitoring systems with automatic alerts to prevent downtime, as even a small temperature fluctuation can damage sensitive servers.

- Hotel Properties: Conducting semi-annual leak detection surveys, especially before peak season, is a key strategy to prevent major system failures that could impact guest comfort and revenue.

Actionable Tips for Implementation

To integrate effective refrigerant management into your maintenance routine, follow these best practices:

- Maintain a Detailed Refrigerant Log: Keep a strict record of all refrigerant additions, including the date, amount added, technician, and the reason for the top-off. This log is legally required by the EPA for systems with over 50 pounds of refrigerant and is crucial for identifying chronic leaks.

- Invest in a Quality Electronic Leak Detector: Modern electronic detectors are highly sensitive and can quickly pinpoint the source of even minuscule leaks, saving hours of diagnostic time compared to older methods.

- Check Leak-Prone Areas First: Focus initial inspections on common failure points like valve stems, flare fittings, service ports, and brazed joints, as these are often the first places leaks develop.

- Stay Updated on Regulations: Refrigerant regulations are constantly evolving. Staying informed about phase-out schedules (like R-22) and new requirements for low-GWP refrigerants ensures your facility remains compliant. You can find essential top AC refrigeration tips on floridacoolinggroup.com that cover best practices for modern systems.

3. Condenser and Evaporator Coil Cleaning

A critical, yet often overlooked, part of any commercial HVAC maintenance checklist is the thorough cleaning of condenser and evaporator coils. These coils are the heart of your system's heat exchange process. The evaporator coil absorbs heat from inside your building, while the condenser coil releases it outside. Over time, they become caked with dirt, grime, and debris, which acts as an insulator and severely impairs this vital heat transfer.

When coils are dirty, your HVAC system has to run longer and harder to achieve the desired temperature, driving up energy consumption and putting immense strain on the compressor. Regular, professional cleaning restores this efficiency, directly impacting your utility bills and extending the lifespan of your equipment. This task is essential for maintaining peak performance and preventing system breakdowns, especially during periods of high demand.

Why It's a Critical Step for Efficiency

Neglecting coil cleaning is like making your HVAC system run a marathon while wearing a heavy winter coat. It will struggle to perform, overheat, and eventually fail. Clean coils facilitate effortless heat transfer, allowing the system to cool or heat your space quickly and efficiently. This directly translates to lower operating costs and a more reliable system.

- Restaurant Chains: Perform bi-annual coil cleaning to combat grease and cooking oil buildup, with some reporting energy bill reductions of up to 20%.

- School Districts: Implement comprehensive coil maintenance programs during the summer to ensure systems are ready for the high-use periods when students return.

- Healthcare Facilities: Conduct quarterly antimicrobial coil treatments to prevent biological growth like mold and bacteria, ensuring high indoor air quality for patient safety.

Actionable Tips for Implementation

Integrate these best practices into your maintenance routine to keep your system's coils in prime condition:

- Schedule Pre-Season Cleaning: Clean outdoor condenser coils every spring before the heavy cooling season begins. This ensures the system is ready for peak demand.

- Use the Right Tools: Use a fin comb to gently straighten any bent coil fins before cleaning, as this maximizes airflow and improves heat exchange. Always use a pH-neutral, non-corrosive coil cleaner specifically designed for HVAC use.

- Document Everything: Photograph coils before and after cleaning. This visual record provides clear documentation of the work performed and the improvement in condition for facility management records. For a deeper dive into the process, you can find more information on how to clean air conditioning coils.

- Keep Surroundings Clear: Regularly clear away vegetation, leaves, and debris from around outdoor condenser units to maintain at least two feet of clearance for proper airflow.

These key takeaways highlight how diligent coil maintenance is a direct investment in your HVAC system's energy efficiency and long-term health.

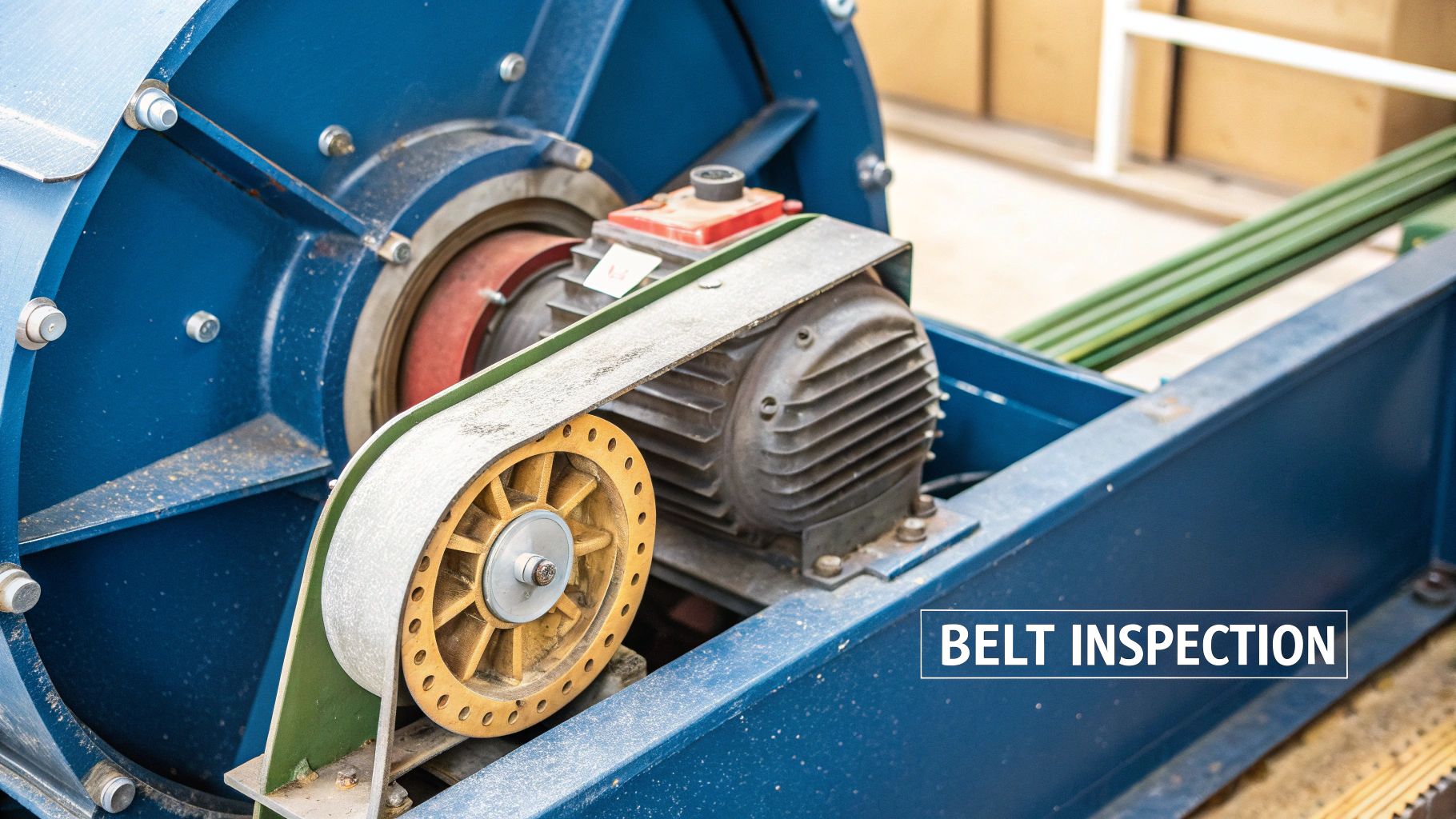

4. Belt and Pulley System Inspection

In many commercial HVAC systems, belt-driven fans are the workhorses that move conditioned air throughout the building. The belts and pulleys that power these fans are critical components, and their failure can lead to an immediate and total system shutdown. A thorough belt and pulley inspection is a non-negotiable part of any comprehensive commercial HVAC maintenance checklist.

This essential task involves checking for proper belt tension, alignment, and signs of wear such as cracks, glazing, or fraying. It also includes inspecting the pulleys for damage or misalignment, which can rapidly destroy even brand-new belts. Neglecting this mechanical heart of your air handler is a direct path to unexpected downtime, inefficient operation, and noisy performance.

Why It's a Critical First Step

A snapped belt means the fan stops, and airflow ceases instantly. This single point of failure can disrupt business operations, affect tenant comfort, and lead to emergency repair calls. Proactive inspection ensures the system operates reliably and efficiently, preventing the collateral damage that can occur when a belt fails catastrophically.

- Industrial Facilities: Implementing predictive belt monitoring with regular visual checks can reduce unexpected fan failures by over 40%, safeguarding production schedules.

- University Campuses: Technicians often conduct monthly belt inspections during peak heating and cooling seasons to ensure classroom and lab ventilation systems remain operational.

- Multi-Tenant Office Buildings: Keeping a well-organized inventory of common belt sizes on-site allows for rapid replacement, minimizing tenant complaints and operational disruptions.

Actionable Tips for Implementation

Integrate these best practices to ensure your belt and pulley systems are always in peak condition:

- Replace Belts in Matched Sets: When a system uses multiple belts, always replace them all at the same time with a matched set. Mixing old and new belts causes uneven tension and premature failure of the new belt.

- Check Tension After Run-In: New belts stretch and seat into the pulley grooves after installation. Re-check and adjust the tension after the first 24-48 hours of operation to ensure optimal performance and longevity.

- Use a Tension Gauge: Don't rely on the "rule of thumb" method. Use a proper belt tensioning gauge to set the tension to the manufacturer's exact specifications, preventing slippage (too loose) or bearing damage (too tight).

- Never Pry Belts On: Forcing a belt over a pulley flange can damage the internal tensile cords, leading to a drastically shortened lifespan. Always loosen the motor mount to release tension for installation and removal.

5. Electrical Connection and Control System Testing

A comprehensive inspection of electrical components and controls is a non-negotiable part of any commercial HVAC maintenance checklist. The electrical system is the nervous system of your HVAC equipment, controlling every function from startup to shutdown. This task involves tightening connections, testing voltage and amperage, inspecting contactors for wear, and verifying control system accuracy.

Loose wires, corroded terminals, and failing relays are not just causes of system breakdowns; they are significant fire hazards. By meticulously testing these components, technicians can prevent catastrophic failures, ensure safe operation, and maintain the system’s responsiveness and efficiency.

Why It's a Critical Safety and Reliability Check

Ignoring the electrical integrity of your HVAC system is like driving a car with faulty wiring. It's a risk that can lead to sudden, expensive, and dangerous outcomes. Regular electrical testing ensures that safety controls function correctly, components receive stable power, and the entire system operates as designed, protecting both your property and its occupants.

- Hospitals: One facility implemented quarterly thermal imaging scans on its critical HVAC electrical panels. This proactive measure identified three overheating connections that were potential fire hazards, preventing costly downtime and ensuring patient safety.

- Shopping Malls: A large retail center upgraded its legacy controls to a modern, smart system with continuous monitoring. This provided real-time alerts on electrical fluctuations, helping to preempt motor failures and reduce energy waste.

- Corporate Headquarters: By conducting annual comprehensive electrical audits on its HVAC units, a corporate campus reduced equipment failures by 45% and extended the lifespan of its rooftop units.

Actionable Tips for Implementation

To ensure electrical maintenance is thorough and effective, integrate these professional-grade practices:

- Use Thermal Imaging: A thermal imaging camera is the fastest way to spot problems. It visually identifies "hot spots" caused by loose connections or failing components before they can cause a major outage or fire.

- Follow Torque Specifications: Don't just tighten connections until they "feel" right. Use a calibrated torque wrench to tighten all electrical terminals to the manufacturer's exact specifications to prevent over-tightening or loose connections.

- Document Baseline Readings: During each service, record the voltage and amperage readings for major components like compressors and fan motors. This data creates a baseline that makes it easy to spot deviations and diagnose developing problems on future visits.

- Test All Safety Controls: Manually test every safety control, including high-pressure cutouts, low-pressure switches, and freeze stats. Verifying these fail-safes are operational is crucial for preventing catastrophic equipment damage.

6. Drain Line and Condensate System Maintenance

A crucial, yet often overlooked, part of any commercial HVAC maintenance checklist is the condensate drain system. As your HVAC unit cools the air, it removes moisture that collects in a drain pan and is routed away through a drain line. If this system clogs, water backs up, potentially causing significant water damage, fostering mold growth, and triggering system shutdowns.

A blocked drain line can lead to overflow that damages ceilings, walls, and expensive equipment. It also creates a breeding ground for algae, fungi, and bacteria, which can compromise indoor air quality. Regular maintenance of these components is a low-cost, high-impact task that prevents expensive emergencies and protects your property.

Why It's a Critical First Step

Ignoring the condensate system is a direct invitation for water-related disasters and system failures. When a drain clogs, a float switch will often shut down the entire HVAC unit to prevent overflow, leading to unexpected downtime. Proactive cleaning ensures continuous operation, protects building materials, and maintains a healthy, mold-free environment.

- Hotels: In humid climates, hotels that perform monthly drain line treatments often prevent dozens of emergency calls for water leaks in guest rooms each cooling season.

- Data Centers: These mission-critical facilities often use UV lights directly in the drain pans to continuously prevent any biological growth, protecting sensitive IT hardware from moisture.

- Restaurants: Implementing weekly drain checks as part of closing procedures helps prevent slip hazards and health code violations caused by overflowing drain pans.

Actionable Tips for Implementation

To ensure your condensate system remains clear and functional, integrate these straightforward practices into your maintenance routine:

- Use Algaecide Tablets: During the cooling season, place slow-release algaecide or biocide tablets in the drain pan. These tablets dissolve over time, preventing the growth of slime and algae that cause clogs.

- Test Condensate Pumps: If your system uses a condensate pump, test it monthly by pouring water into the reservoir to ensure the float switch engages and the pump properly evacuates the water.

- Clear Clogs Safely: Use a wet/dry vacuum to suction out stubborn clogs from the termination point of the drain line. This method is often safer and more effective than using compressed air, which can damage fittings.

- Install Cleanout Ports: Adding accessible T-shaped cleanout ports to drain lines makes it significantly easier to flush and inspect them without having to disassemble piping.

7. Motor and Bearing Lubrication

Proper lubrication of motors, bearings, and other rotating components is the lifeblood of a commercial HVAC system’s mechanical health. This critical task prevents the friction that leads to overheating, excessive wear, and catastrophic equipment failure. It involves applying the correct type and amount of lubricant to motor bearings, fan bearings, and other moving parts at precise intervals.

While many modern motors have sealed bearings that are permanently lubricated, a significant amount of equipment, especially in older systems, requires a diligent lubrication schedule. Overlooking this step is a direct path to seized motors and costly, unplanned downtime, making it a non-negotiable part of any comprehensive commercial HVAC maintenance checklist.

Why It's a Critical Mechanical Step

Ignoring lubrication is like running an engine without oil. It guarantees failure. The metal-on-metal contact generates intense heat and friction, rapidly degrading components. Proper lubrication creates a protective film that reduces this friction, dissipates heat, and prevents corrosion, ensuring motors and fans operate smoothly and efficiently for their full intended lifespan.

- Manufacturing Facilities: Implementing ultrasonic monitoring to listen for bearing friction can reduce lubrication-related bearing failures by over 60%, pinpointing exactly when grease is needed.

- Hospitals: Switching to high-performance synthetic lubricants can safely extend maintenance intervals by up to 50%, reducing disruptions in critical environments.

- School Districts: Training in-house staff on proper greasing techniques for air handlers and exhaust fans can save tens of thousands of dollars annually in outsourcing costs and premature equipment replacement.

Actionable Tips for Implementation

To build a reliable lubrication program, focus on precision and documentation rather than guesswork.

- Follow Manufacturer Specifications: Always use the exact type of lubricant (e.g., polyurea-based, lithium complex) specified by the equipment manufacturer. Using the wrong grease can cause chemical reactions that destroy the lubricant's properties.

- Clean and Purge Correctly: Thoroughly clean grease fittings (zerks) before attaching the grease gun to prevent forcing contaminants into the bearing. Add new grease slowly while the motor is running, if safe, until you see a small bead of fresh grease emerge from the bearing seal. This purges the old, broken-down grease.

- Label and Log Everything: Label each lubrication point with the required lubricant type and service frequency. Maintain a detailed logbook or digital record for each asset, noting the date, technician, and amount of grease added. This history is invaluable for identifying recurring issues.

8. Thermostat Calibration and Building Automation System (BAS) Optimization

Your HVAC system's controls are its brain, and ensuring they are calibrated and optimized is fundamental for efficient operation. This task involves verifying that thermostats accurately read room temperatures and that the Building Automation System (BAS) is programmed with the most efficient schedules and control sequences. It is the command center for both energy management and occupant comfort.

When thermostats are inaccurate or the BAS is poorly configured, the entire system operates on flawed data. This leads to energy waste, uncomfortable temperature swings, and unnecessary wear on equipment. Proper calibration and optimization ensure your HVAC system responds intelligently to the building's actual needs, rather than running inefficiently based on incorrect information.

Why It's a Critical First Step

Ignoring control systems is like driving a high-performance car with a faulty speedometer and a bad GPS. You waste fuel and never reach your destination comfortably. Calibrated controls prevent the system from overcooling or overheating, directly impacting your utility bills. An optimized BAS can reduce HVAC energy consumption by 20-30% while maintaining a consistent and comfortable environment. The future of precise temperature control and energy management for HVAC systems often lies in advanced Internet of Things building automation, which relies heavily on accurate data.

- University Campus: A large university saved over $200,000 annually by implementing optimal start/stop algorithms in its BAS, ensuring buildings reached comfortable temperatures just as occupants arrived.

- Corporate Office: A corporate headquarters reduced its energy costs by 25% by integrating demand-controlled ventilation logic into its BAS, adjusting fresh air intake based on real-time CO2 levels.

- Retail Chain: A national retailer deployed a cloud-based BAS across 500 locations, enabling centralized monitoring and energy management that standardized comfort and cut costs.

Actionable Tips for Implementation

To integrate control optimization into your commercial HVAC maintenance checklist, follow these best practices:

- Verify Accuracy: Use a calibrated digital thermometer placed next to a thermostat to verify its reading. If there's a discrepancy of more than 2°F, the thermostat should be recalibrated or replaced.

- Program Smart Schedules: Implement setback temperatures for unoccupied periods, such as nights and weekends. Utilize optimal start/stop algorithms so the system only runs as long as needed to achieve setpoints by the time occupants arrive.

- Review BAS Trend Data: Monthly, analyze BAS data logs to spot anomalies like equipment short-cycling, unusually long runtimes, or simultaneous heating and cooling. These trends often indicate a need for maintenance or optimization. Setting the right temperature can be complex, and you can learn more about recommended thermostat settings for different conditions.

8-Point Commercial HVAC Maintenance Checklist Comparison

| Maintenance Task | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Air Filter Inspection and Replacement | Low to medium; basic to intermediate | Moderate; filters, pressure gauges | Improves air quality; saves 5-15% energy | High-traffic commercial buildings | Simple, cost-effective, prevents failure |

| Refrigerant Level Check and Leak Detection | High; requires certified technicians | High; specialized equipment, EPA compliance | Maintains efficiency; prevents compressor damage | Facilities with refrigerant systems | Compliance, early leak detection, protects equipment |

| Condenser and Evaporator Coil Cleaning | Medium to high; requires equipment | Medium to high; chemicals, pressure washers | Improves efficiency by 15-35%; reduces energy cost | Buildings needing heat transfer efficiency | Significant energy savings, extends equipment life |

| Belt and Pulley System Inspection | Low to medium; needs specific tools | Low to medium; tension gauges, replacement belts | Prevents downtime; improves efficiency | Systems with belt-driven fans/blowers | Prevents failures, inexpensive maintenance |

| Electrical Connection and Control Testing | High; licensed electricians advised | High; specialized testing equipment | Prevents electrical hazards; improves reliability | Complex HVAC systems prioritizing safety | Prevents fires, extends equipment life, reduces energy waste |

| Drain Line and Condensate System Maintenance | Low; routine flushing and inspection | Low; cleaning supplies, biocides | Prevents water damage, mold growth | Humid climates, moisture-prone systems | Simple, prevents damage and odors |

| Motor and Bearing Lubrication | Medium; requires lubrication knowledge | Low to medium; grease guns, lubricants | Extends life; reduces noise/vibration | Older or unsealed motor equipment | Reduces failures, improves efficiency |

| Thermostat Calibration and BAS Optimization | Medium to high; specialized BAS knowledge | Medium; software, calibrated tools | Saves 15-30% energy; improves comfort | Buildings with BAS or multiple zones | Energy savings, occupant comfort, proactive maintenance |

Partnering for Peak Performance: Your Next Steps

Navigating the complexities of commercial HVAC systems can seem daunting, but as we've detailed, a structured, proactive approach makes all the difference. This comprehensive commercial hvac maintenance checklist moves beyond a simple to-do list; it's a strategic framework for safeguarding your investment, ensuring operational continuity, and managing long-term costs effectively.

By systematically addressing the core components—from the foundational task of replacing air filters to the more technical aspects of calibrating building automation systems—you create a powerful defense against unexpected breakdowns and performance degradation. You're not just fixing problems; you are preventing them from ever occurring.

From Checklist to Action: The Path Forward

The true value of this guide lies in its implementation. Simply knowing that condenser coils need cleaning or that electrical connections must be checked is only the first step. The real return on investment comes from turning this knowledge into a consistent, scheduled maintenance routine tailored to your specific equipment and operational demands.

Consider the interconnected nature of your HVAC system. A clogged drain line (Item 6) can lead to water damage and electrical shorts (Item 5). A worn belt (Item 4) can strain the motor and bearings (Item 7), leading to premature failure. This domino effect is why a holistic maintenance plan, covering all eight critical points, is non-negotiable for any serious business owner or property manager.

Key Takeaway: Proactive maintenance isn't an expense; it's an investment in efficiency, reliability, and peace of mind. Every task on this checklist directly contributes to lower energy bills, a longer system lifespan, and a more comfortable indoor environment for your employees and customers.

Your Most Valuable Asset: A Trusted HVAC Partner

While your in-house facilities team can handle some basic tasks like filter changes, the majority of this checklist requires specialized tools, diagnostic equipment, and certified expertise. Tasks involving refrigerant levels, electrical controls, and motor lubrication carry significant risks if performed incorrectly. This is where a professional partnership becomes essential.

For businesses and property managers throughout Palm Beach County, from the bustling storefronts of Boca Raton to the commercial hubs of Delray Beach, having a reliable HVAC partner is critical. A qualified team of technicians can:

- Customize Your Plan: Adapt this commercial hvac maintenance checklist to the unique needs of your specific system, building size, and usage patterns.

- Provide Advanced Diagnostics: Utilize thermal imaging, refrigerant leak detectors, and multimeters to identify underlying issues before they escalate.

- Ensure Compliance and Safety: Handle refrigerants and high-voltage electrical components according to strict industry regulations and safety protocols.

Ultimately, a proactive maintenance strategy transforms your HVAC system from a potential liability into a reliable, high-performing asset. It’s about taking control, minimizing risk, and ensuring your system is ready to handle the demanding South Florida climate without fail. Don't wait for a system failure to force your hand; the time to act is now.

Ready to implement a professional, customized commercial HVAC maintenance checklist for your business? The NATE-certified technicians at Florida Cooling Group are available 24/7 to provide expert service and create a proactive maintenance plan that protects your investment and ensures year-round comfort. Contact Florida Cooling Group today to schedule your comprehensive system evaluation.

(561) 400-2205

(561) 400-2205